3 Factors for An Effective Safety Program. 1. Have A Policy 2. Employee Training. 3. Implementation. Learn more by watching our video!

Warming up is key to being ready to work and reducing strains. Check out our link for our Stretch and Flex Routine video.

Check out our new post for National Ladder Safety Month. Check out the links below to OSHA ladder safety regulations and the NIOSH Ladder Safety App downloadable to iOS or Android devices. NIOSH Ladder Safety App: iOS: https://apps.apple.com/us/app/ladder-safety/id658633912 Android: https://play.google.com/store/apps/details?id=gov.cdc.niosh.dsr.laddersafety&hl=en_US&gl=US

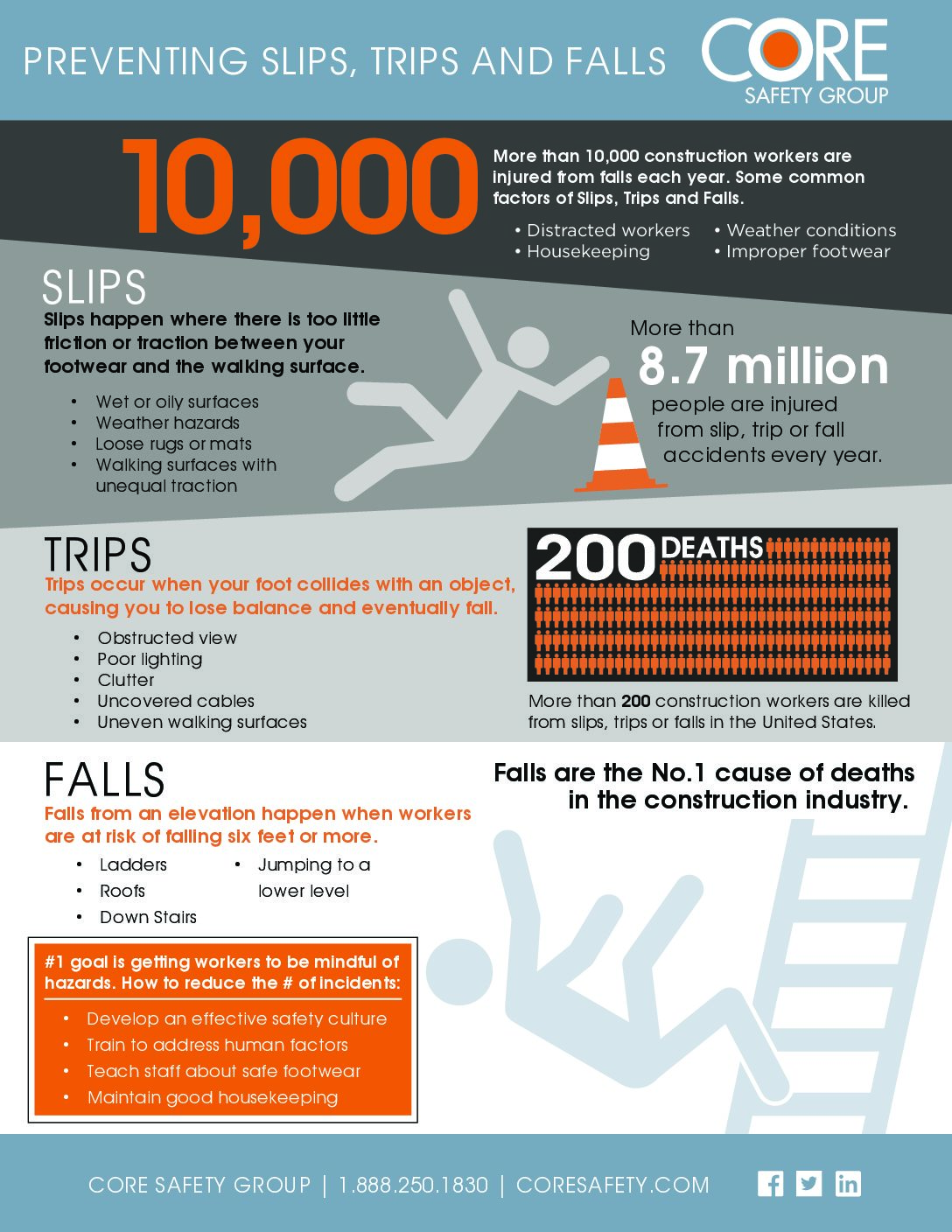

Slips, trips and falls can result in sprains and strains, cuts and bruises, broken bones and more. Slips and trips occur when there’s an unintended or unexpected change in contact between the feet and the ground or other walking-working surface.

Download our Slips, Trips and Falls Poster!

Slips occur when too little friction or traction is present between a worker’s footwear and the walking surface. Common causes of slips include:

- wet or oily surfaces,

- weather hazards,

- or lose ground.

Trips occur when a worker’s foot makes contact with an object resulting in a loss of balance and a fall. Common causes of tripping include:

- poor lighting,

- obstructed views,

- or uneven walking surfaces.

Click the video below to learn more!

If you need assistance preventing slip, trips and falls at your work location, call CORE Safety!

As we begin 2020, now is good time to take a deep dive into your company’s safety manual. In a lot of cases, companies will comprise a safety manual and several years will pass without a review of their programs. And during that time

- new regulations are introduced,

- best practices evolve,

- and company operations change.

We recommend that as an organization your safety manual is reviewed and updated at least once a year.

If your team needs assistance dusting off your safety manual and ensuring that you are up to date with federal regulations and industry standards, Call CORE Safety.

Employee training is paramount to the success of a safety program. It is also critical that the training be documented, and files retained to ensure that your organization is audit ready.

Employers have an obligation to put new employees through an orientation process and provide certain safety training before they are allowed to go to work.

It is also important to train workers any time a process is changed or new tools and equipment are introduced to the task.

There are so many different topics that workers could, should or must be trained on to ensure that they are prepared to do their jobs safely. Whether that’s fall protection, PPE, hazardous communication, hazard recognition, the list goes on. Refresher training is also important to keep workers up to date.

And again, keeping the employees’ training files organized and readily available ensures that you are ready for any sort of inspection by an enforcement agency.

If you need help evaluating your training programs or would like us to deliver training to your team, don’t hesitate to give Core Safety a call.

When we think of people whose inventions have made significant impacts to our world we tend to think of Thomas Edison and the lightbulb or Karl Benz and the automobile. But in the construction industry we should thank Edward Bullard, because 100 years ago in 1919 he invented the hard had, which today is the most recognizable and common PPE item and is responsible for protecting countless people while they work.

As we all know PPE is our last line of defense from hazards. If we can’t eliminate a hazard by other means we are left with having to implement a form of personal protective equipment.

Throughout the years more and more PPE items have become common or even mandatory for example, most project sites require:

- hard hats

- safety glasses

- high visibility clothing

- or reflective vest to be worn at all times.

OSHA has a general safety standard requiring employers to ensure that appropriate PPE is worn in all operations where there is an exposure to hazardous conditions. So, whether it’s a hard hat, safety glasses, gloves, face shield, Kevlar sleeves, respirators, the list goes on it’s important for the employer to provide what the employee needs. It’s always important for employees to understand the proper use, selection and maintenance of PPE.

If you’re in need of some help evaluating your PPE or training your team, don’t hesitate to give us a call.

The OSHA standard for protecting reinforcing steel can be found in 1926 subpart Q for concrete and masonry construction.

1926.701(b) states all protruding reinforcing steel, onto and into which employees could fall, shall be guarded to eliminate the hazard of impalement.

Exposure to impalement is always a concern when employees are working above rebar or other sharp protrusions. Protection is typically provided by using caps or covers made of plastic, wood or metal.

One issue we see when walking project jobsites, is when companies use the mushroom style plastic covers to provide impalement protection. These types of covers are suitable protection from scratches ONLY and cannot be used for impalement protection.

Click the link below to watch the full video!

Learn more about the importance of safety inspections!

In construction a large portion of work is performed outdoors. Extreme temperatures influence worker safety and during summer months workers are at a greater risk for heat stress.

Heat stress is the overall heat load on the human body that includes temperature, humidity and radiant heat in the thermal environment, and metabolic heat generated by physical activities.

Heat illness is the result of the body’s inability to expel heat, causing excessive sweat loss or an overly high body core temperature. Ailments that can arise because of excess heat are heat stroke, heat exhaustion, heat syncope, heat cramps and heat rash.

To combat the effects of working in the heat, employees and employers must use certain strategies.

- Acclimatization is the physiological adaptation of the human body to heat. Employee should gradually increase their work intensity and duration and exposure to the heat during this acclimatization period.

- Next you can adjust your shift times to have employees start earlier in the day to avoid working during the hottest part of the day.

- Maintain a state of hydration. Drink water frequently, not just when you feel thirsty. Click here (English & Spanish) to view our info-graphic that helps explain this.

- Train workers on the signs and symptoms of heat illness.

Follow the link below to watch our full video!

If you need some help training your workers on heat illness prevention or you would like someone to help with your heat illness prevention plan. Don’t hesitate to give us a call!