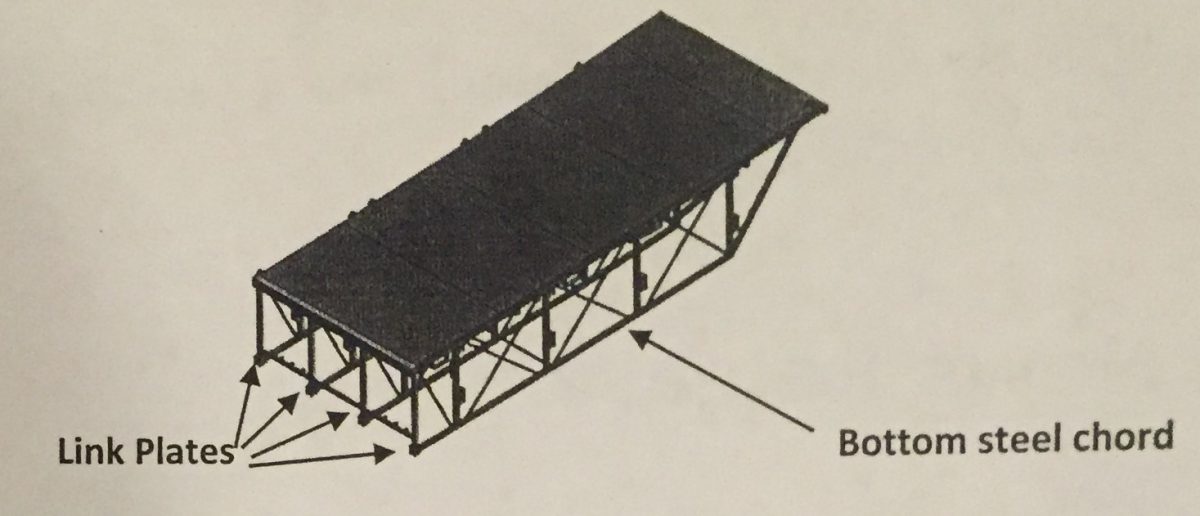

Hydro Mobile has issued a “Technical Notice” involving bearing bridge application with their equipment. There have been at least two cases where the steel cords on the bottom of the bridge sections in the link plate attachment were damaged beyond repair. This damage was caused by rust, due to inadequate inspections, maintenance and storage, that lead to failure of the bridge section. It is the owners’ ‘duty of care’ to inspect these cords. Frequent (3 month) and annual inspections (ANSI A92.9 and OSHA 1926.451(f)(3) and (4)) must be done by a ‘qualified’ person. These inspections must also have written records that are kept for 4 years. Hydro Mobile is requiring all bridges 10 years or older be immediately inspected.

Hydro Mobile has developed the following 3-point inspection to address concerns of the bridge section.

- Finalizing inspection methods that would utilize a torqued testing bracket that can be mounted on potentially affected chords with a ½ inch bolt with a ¼ inch steel peg/punch that when tightened can identify any weak areas in the chord.

- Hydro Mobile have partnered with SGS, a material testing company with 1,500 locations nationwide, to 1) upon request, come to an equipment owners’ yard or jobsite to conduct ultrasonic testing 2) train equipment owners on ultrasonic testing equipment related to where to test and what the material thickness should be (bottom chords and link plates).

- Hydro Mobile has also established a trade-in offer which allows equipment owners to purchase new equipment.