The Machine Guarding for Supervisors for Manufacturing online training from ClickSafety is a 60-minute introductory-level course for Manufacturing Supervisors to provide the knowledge and information they need to keep employees safe in a Manufacturing facility where machines are operated and maintained.

Throughout this course, participants can expect to learn special tips for identifying risks associated with machinery operation, as well as find links to videos and materials directly from OSHA, the Department of Labor (DOL), and the CDC. It is one of the most robust machine guarding awareness courses for Manufacturing online.

ClickSafety’s Machine Guarding for Supervisors for Manufacturing is designed specifically to aid Supervisors in their role in the Manufacturing workspace as it applies to machinery and machine guarding. Because responsibilities range from lockout/tagout (LOTO) compliance to coordinating with contractors and providing oversight, this course’s topics include the following:

- The three broad categories of hazards – caught in, struck by, and burn hazards

- A thorough overview of basic machinery parts including specific examples for each: the point of operation, power transmission devices, and operating controls

- Information about the basic types of hazardous mechanical actions from rotating parts and in-running nip point to reciprocating and transverse actions

- The nuances among cutting, punching, shearing, and bending hazardous actions

- Details on common hazardous activities from setup and inspection to clearing jams and making adjustments to cleaning, lubricating, and other maintenance tasks.

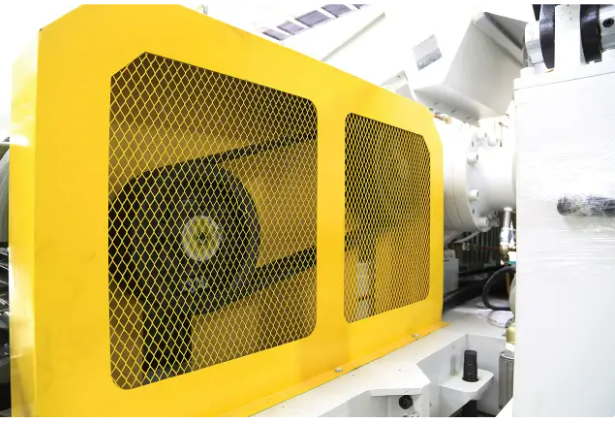

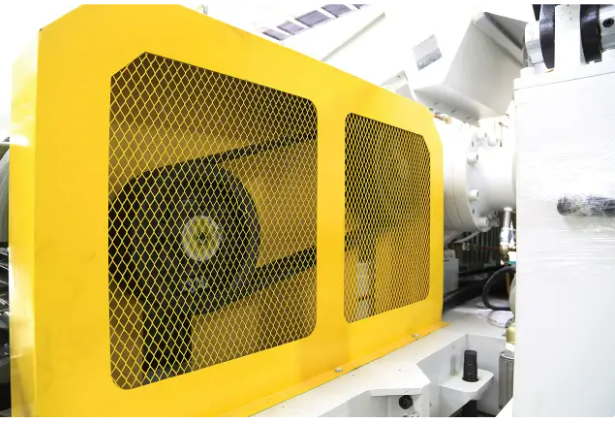

- Very specific knowledge about machine guarding during normal operations and the value of machine guards

- Condition-focused details for conditions like service and maintenance: lockout/tagout (LOTO)

- Helpful material regarding the different types of machine guards (fixed, adjustable, self-adjusting, interlocking barrier guards, and Type A and B gates)

- Details about safeguarding devices used to protect machine operators such as pullback, restraint, presence-sensing devices, and two-handed controls and trips

- Safeguarding by location – the safe distance – information for safe holding, safe opening, gravity feed, and automatic/semiautomatic feeding and injection methods

- OSHA requirement minimums for machine guarding – to prevent contact, to be secure, and to create no new hazards

- Supervisor-specific knowledge relative to all aspects of machine guarding in a manufacturing environment